Compressor Checklist Template

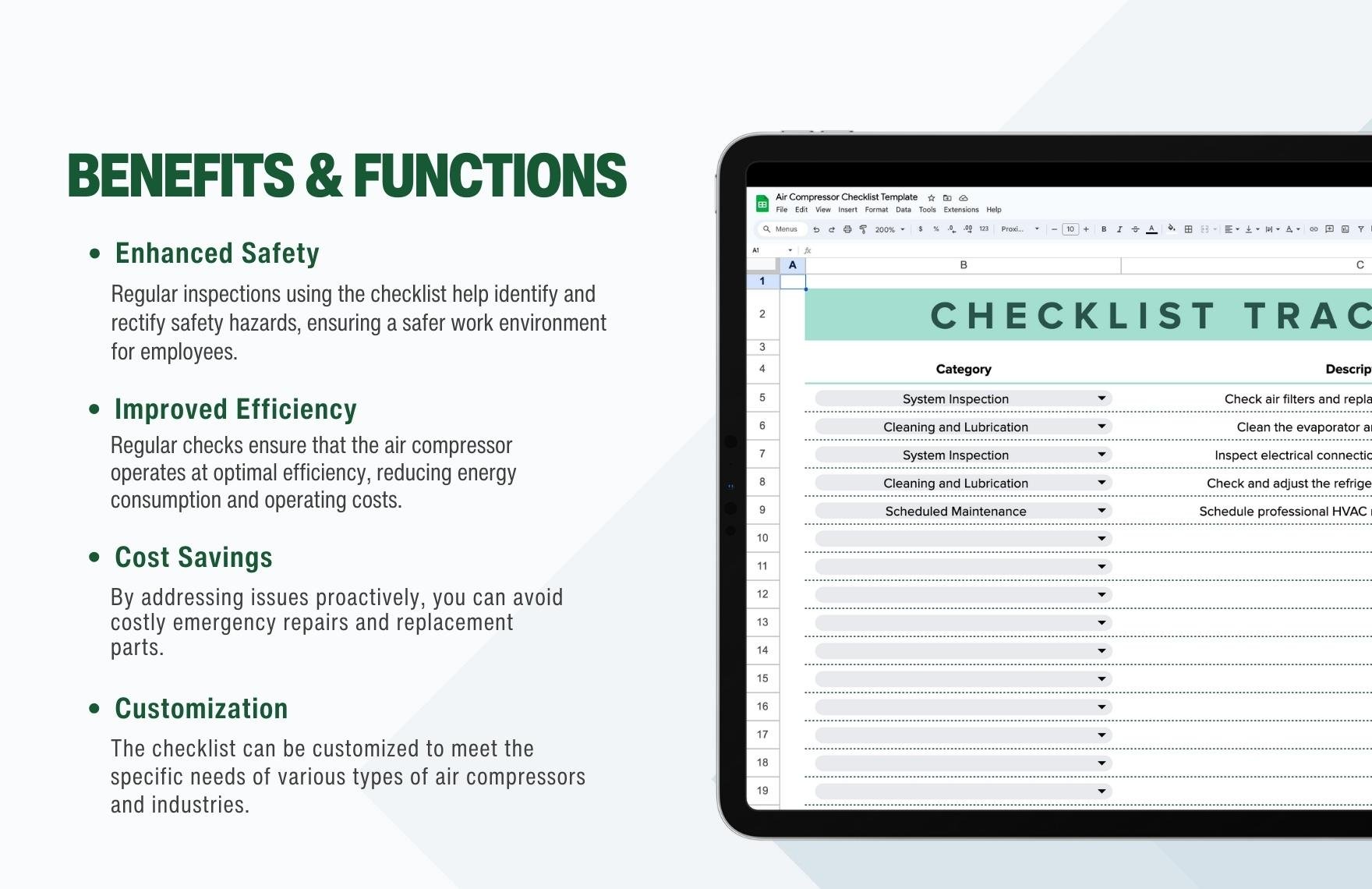

Compressor Checklist Template - Use the dynamic button to enter as many compressors as possible. Use the dynamic button to enter as many compressors as possible. Download or preview 1 pages of pdf version of compressors inspection checklist (doc: This document is a preventative maintenance checklist for an air compressor. The templates available in our public library have been created by our customers and employees to help get you started using safetyculture's solutions. To ensure efficient operation and longer life of the air compressor, a routine maintenance schedule should be followed. Use this air compressor preventive maintenance checklist to inspect multiple air compressors in operation. It contains a table to record daily checks of items like lubricant oil, motor, belts, starters, loose parts, air lines,. 83.6 kb ) for free. Use the air compressor preventive maintenance checklist for weekly, quarterly, and monthly inspections, ensuring optimal performance of air compressors. It contains over 30 inspection points covering the general appearance, engine compartment, and. Check, clean and change components. Optimize equipment reliability with our air compressor inspection checklist template, ideal for maintenance professionals. Use this compressor preventive maintenance checklist to inspect multiple air compressors in operation. The templates are intended to be used. This daily inspection checklist is used to inspect an air compressor on a monthly basis. The templates available in our public library have been created by our customers and employees to help get you started using safetyculture's solutions. 83.6 kb ) for free. Use the dynamic button to enter as many compressors as possible. This document provides an air compressor inspection checklist template that includes sections for noting the event year, location of the compressor, a legend of potential issues to check for. Check, clean and change components. Use the dynamic button to enter as many compressors as possible. It contains over 30 inspection points covering the general appearance, engine compartment, and. The templates available in our public library have been created by our customers and employees to help get you started using safetyculture's solutions. Use this preventive maintenance checklist for an air. Use the air compressor preventive maintenance checklist for weekly, quarterly, and monthly inspections, ensuring optimal performance of air compressors. The templates are intended to be used. Use the dynamic button to enter as many compressors as possible. 83.6 kb ) for free. This daily inspection checklist is used to inspect an air compressor on a monthly basis. It contains a table to record daily checks of items like lubricant oil, motor, belts, starters, loose parts, air lines,. Use this compressor preventive maintenance checklist to inspect multiple air compressors in operation. Download or preview 1 pages of pdf version of compressors inspection checklist (doc: This document is an inspection checklist for an air compressor. This daily inspection checklist. The templates available in our public library have been created by our customers and employees to help get you started using safetyculture's solutions. Optimize equipment reliability with our air compressor inspection checklist template, ideal for maintenance professionals. Use the dynamic button to enter as many compressors as possible. This checklist simplifies routine maintenance tasks, ensuring the consistent and efficient performance. This checklist simplifies routine maintenance tasks, ensuring the consistent and efficient performance of your air compressor, reducing downtime, and extending its operational life. This daily inspection checklist is used to inspect an air compressor on a monthly basis. It contains 25 items to check regarding safety, mechanical, and electrical aspects of the air compressor. Take photos and add notes for. The templates available in our public library have been created by our customers and employees to help get you started using safetyculture's solutions. This document provides an air compressor inspection checklist template that includes sections for noting the event year, location of the compressor, a legend of potential issues to check for. Use the dynamic button to enter as many. 83.6 kb ) for free. The templates are intended to be used. It contains a table to record daily checks of items like lubricant oil, motor, belts, starters, loose parts, air lines,. Take photos and add notes for each equipment. Optimize equipment reliability with our air compressor inspection checklist template, ideal for maintenance professionals. Test it now for free! Use the dynamic button to enter as many compressors as possible. Check, clean and change components. The templates available in our public library have been created by our customers and employees to help get you started using safetyculture's solutions. This document is a preventative maintenance checklist for an air compressor. Use this preventive maintenance checklist for an air compressor in operation. This document is a preventative maintenance checklist for an air compressor. The templates are intended to be used. Optimize equipment reliability with our air compressor inspection checklist template, ideal for maintenance professionals. Test it now for free! The templates available in our public library have been created by our customers and employees to help get you started using safetyculture's solutions. It contains 25 items to check regarding safety, mechanical, and electrical aspects of the air compressor. Use this preventive maintenance checklist for an air compressor in operation. The templates are intended to be used. This daily inspection. 83.6 kb ) for free. Use the air compressor preventive maintenance checklist for weekly, quarterly, and monthly inspections, ensuring optimal performance of air compressors. To ensure efficient operation and longer life of the air compressor, a routine maintenance schedule should be followed. The templates available in our public library have been created by our customers and employees to help get you started using safetyculture's solutions. Use this preventive maintenance checklist for an air compressor in operation. Use this compressor preventive maintenance checklist to inspect multiple air compressors in operation. It contains 25 items to check regarding safety, mechanical, and electrical aspects of the air compressor. It contains over 30 inspection points covering the general appearance, engine compartment, and. The templates are intended to be used. Download or preview 1 pages of pdf version of compressors inspection checklist (doc: Test it now for free! It contains a table to record daily checks of items like lubricant oil, motor, belts, starters, loose parts, air lines,. This document is a preventative maintenance checklist for an air compressor. Use this air compressor preventive maintenance checklist to inspect multiple air compressors in operation. This daily inspection checklist is used to inspect an air compressor on a monthly basis. This document is an inspection checklist for an air compressor.Air Compressor Checklist Template in Excel, Google Sheets Download

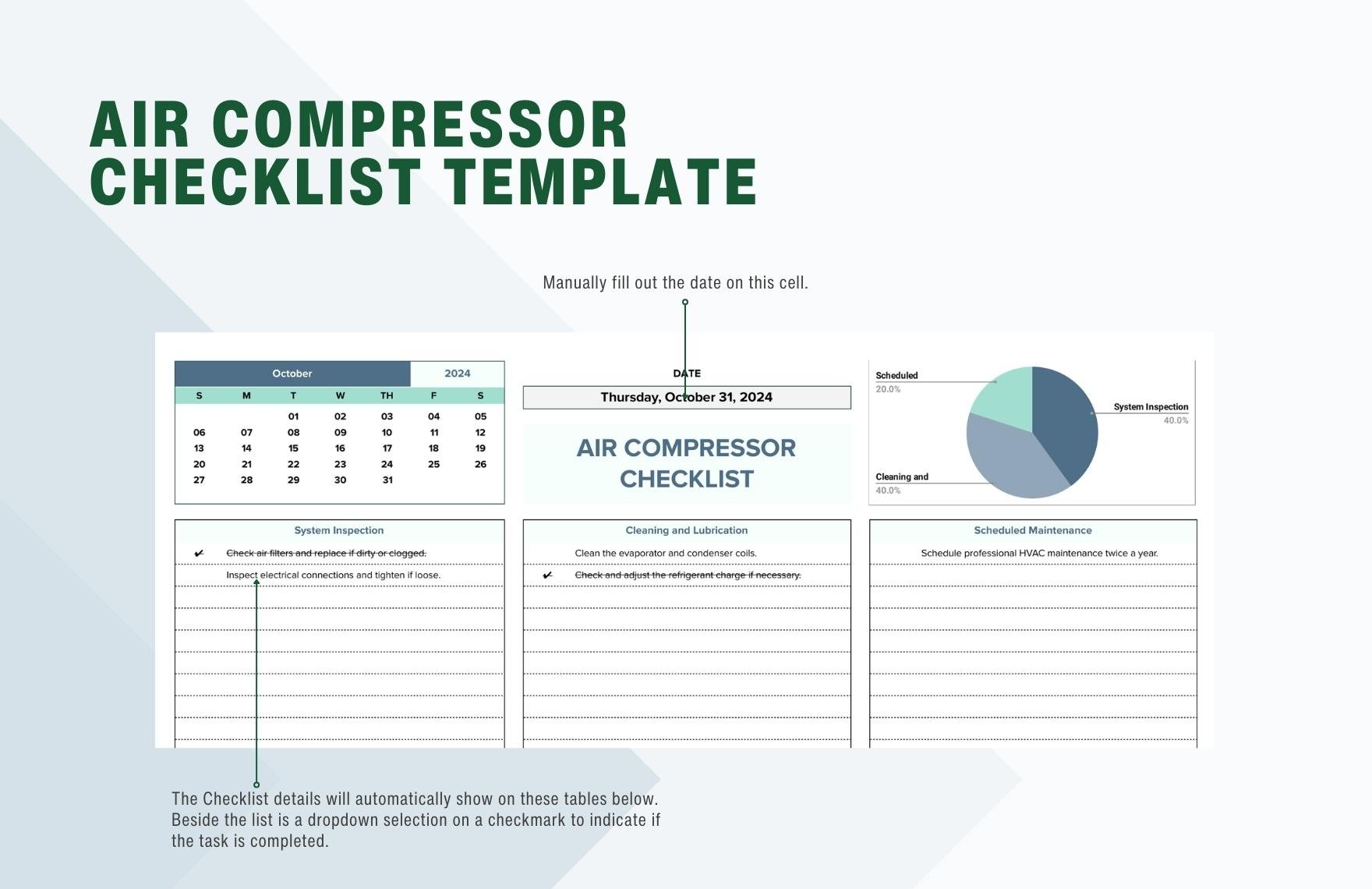

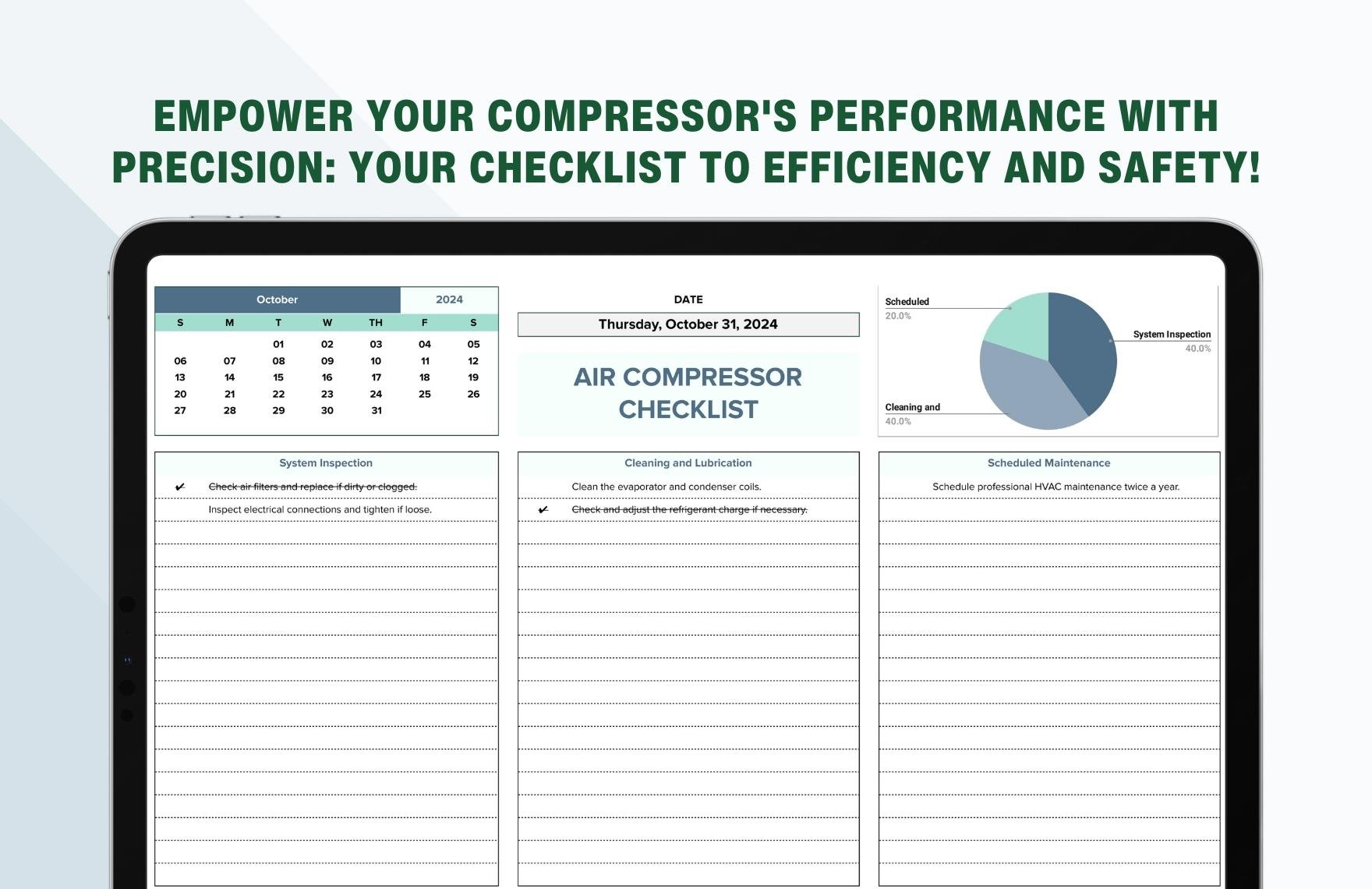

Air Compressor Checklist Template in Excel, Google Sheets Download

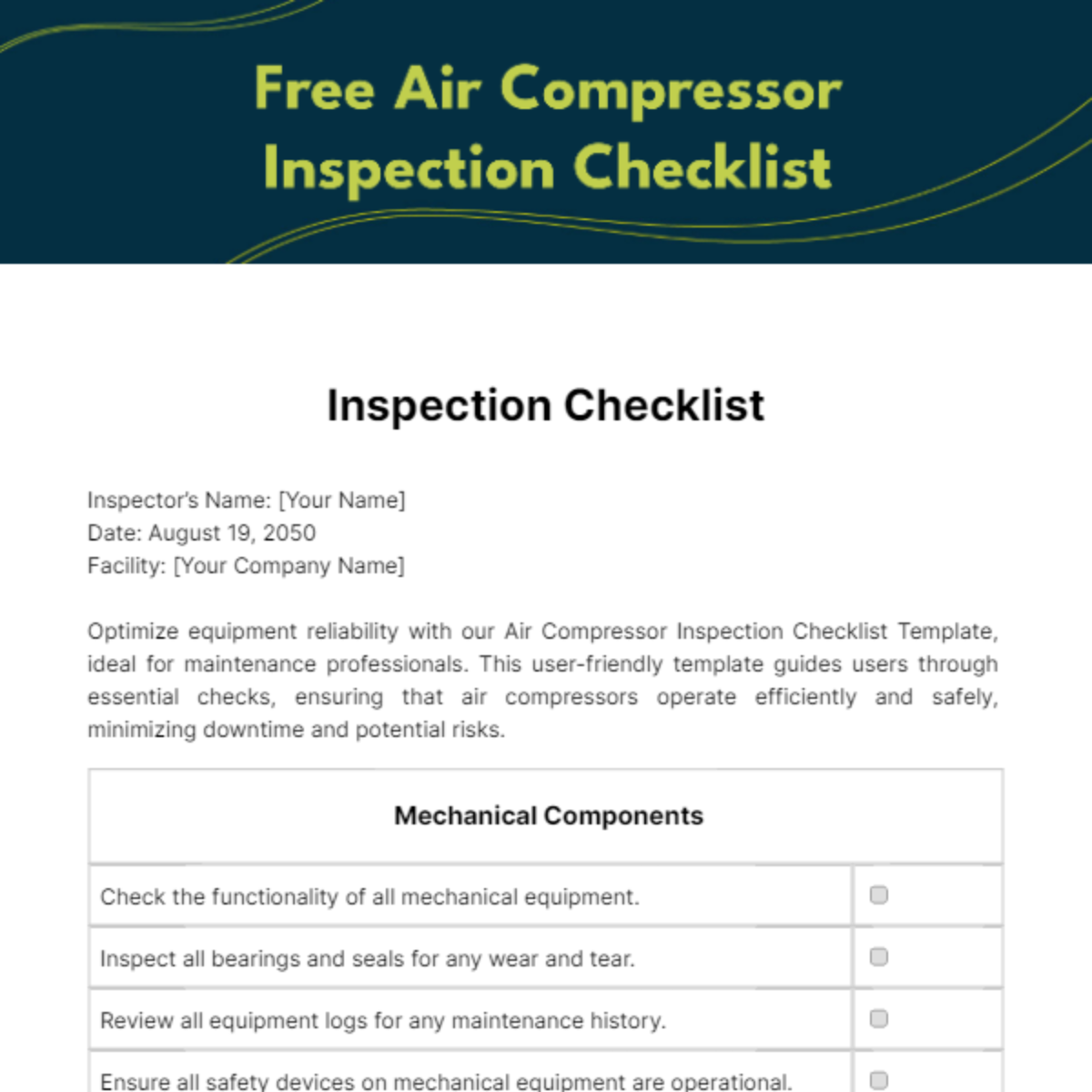

Air Compressor Checklist PDF

01. Air Compressor Daily Checklist

Essential Air Compressor Checklist For Efficient Operations Excel

Quincy Air Compressor Maintenance Checklist

Compressor Inspection Checklist PDF Gas Technologies Gases

Air Compressor Inspection HSE Checklist (1) PDF

Free Air Compressor Inspection Checklist Template Edit Online

Air Compressor Checklist Template in Excel, Google Sheets Download

Use The Dynamic Button To Enter As Many Compressors As Possible.

Check, Clean And Change Components.

This Document Provides An Air Compressor Inspection Checklist Template That Includes Sections For Noting The Event Year, Location Of The Compressor, A Legend Of Potential Issues To Check For.

This Checklist Simplifies Routine Maintenance Tasks, Ensuring The Consistent And Efficient Performance Of Your Air Compressor, Reducing Downtime, And Extending Its Operational Life.

Related Post: